Structural Repair by Epoxy Injection

Structural Repair by Epoxy Injection

Here a low pressure method of epoxy injection utilizes surface mounted ports set with a gel grade epoxy. The technician watches for material communication between ports and makes a point to force material to the full depth of the bond line. This type of injection has the advantage of being less invasive because no drilling is required. After curing ports and gel epoxy are removed to the original surface.

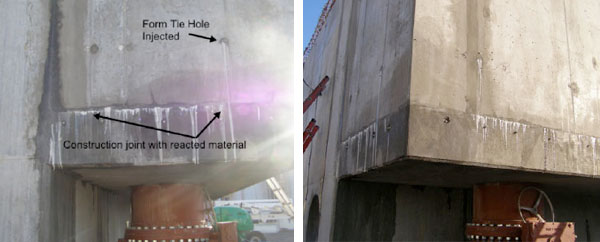

Active Leak Repair by chemical grout injection

Hydro active urethane injection is shown as a means to permanently repair active leaks in a new water treatment structure. Cracks, form ties and construction joints are drilled to intersect at mid wall depth then flushed and injected.

Soil Stabilization by permeation grouting and compression grouting

Soil Stabilization by permeation grouting and compression grouting

Permeation grouting is a method where the resin injected into the ground permeates the soil before it reacts resulting in an underground matrix that is solid, load bearing and impermeable to water. Adjustment of the catalyst component allows control of the material set time.

Inducon Corporation uses this type of injection to stop ground water infiltration in underground structures and in some particular “curtain wall” applications where sheet pile shoring is not possible or feasible.

The Compaction grouting process utilizes chemical grouts whose properties do not allow them to mix with the soil but instead displace the surrounding soil as the volume increases up to twenty times as it goes through its curing process. Typically grout is pumped through vertical pipes which are arranged on a grid thereby compacting the soil in place.

One example of Inducon Corporation’s use of this method is to increase compaction of loose fill inside a foundation wall under a settling slab.